Craft

HANDWORK at the Werkschulheim Felbertal Craft training parallel to school education...

At the Felbertal work training centre, the intensive Crafts lessons throughout the lower school (4-6 lessons per week) is a particular focus. This promotes the practical and creative skills of our pupils.

In the Upper school parallel to the grammar school education, there is a craft apprenticeship, optionally in the following professions Mechatronics, mechanical engineering technology or carpentry technology. This training not only teaches manual skills and solid technical foundations, but also design expertise and problem-solving skills. The craft training is integrated into the course of a school week and lasts 15 to 19 hours per week per school year. The practical lessons take place in small groups in the workshops with a maximum of 8 students per master craftsman.

Our curricula are adapted to the current training regulations and also include a pronounced project-based focus, which is reflected above all in the planning, construction and realisation of an individual final project.

The graduates complete their nine years of schooling with a practical and theoretical final examination and the AHS-Matura. This attractive Double qualification entitles graduates to study at any university of applied sciences or university and also gives them the opportunity to enter professional life as a sought-after specialist. In addition to their professional qualifications, the language skills and holistic thinking of our graduates are highly valued in the business world.

Our special focus throughout the lower school is on intensive technical work lessons, which promote problem-solving skills, independent work and teamwork.

In the extensive craft lessons in the Lower school (4-6 lessons per week per school year) our pupils familiarise themselves with a wide range of materials, tools and processing options.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

In the first and second grades, pupils learn about many different materials, tools and processing options. The tasks from the areas of „product creation/design“, „technology“ and „built environment“ are intended to give the children the opportunity to engage with their living environment in a variety of ways, expand their knowledge and produce workpieces professionally. Their own ideas and conceptions should be incorporated and tried out. The design is based on functional criteria; it is important to us that the materials are processed appropriately.

In the third and fourth years, more extensive workpieces are built precisely according to plans. Pupils spend one semester working with wood as part of the „Product Creation / Design“ programme and one semester working with metal as part of the „Mechanical Engineering“ programme. The construction of a steam engine has already begun. The programme also includes electrical engineering, mechanics and robotics. This makes it easier for students to choose a trade at the end of year 4. At the end of the work focus in the lower school, a musical instrument (tenor ukulele, sister or guitar) is made in one semester in Year 4. In the other semester, the steam engine is completed in the „Machine Technology“ area.

Head of department: Florian Geretschläger

The Mechanical engineer - a profession with a future. Especially today, the economy is looking for qualified managers in the technical field. Mechanical technicians are somewhere between skilled workers and engineers, combining manual skills with technical and business knowledge. A good salary and promotion prospects are guaranteed.

In the first year of training, the focus is on basic skills such as sawing, drilling, turning, milling and thread cutting, supplemented by basic knowledge of electrical engineering. A professional 3/D-CAD drawing programme is used in design theory.

The focus in the second year of training is on steel construction: the forming of steels/non-ferrous metals and the production of joints using various welding processes (such as MIG/MAG, TIG, manual arc welding or soldering), as well as cutting using plasma and autogenous flame cutting.

In the following year, the production of workpieces on computer-controlled machines takes centre stage. CNC technology enables the production of extremely complex parts with up to 5 axes. The programmes are written on CAM software and simulated on the PC. Hydraulic and pneumatic trainers are available to gain an insight into control and regulation technology. In addition, a Stirling engine is built, whereby particular attention is paid to precise, independent and solution-orientated work.

The final stage in year 8 is project-orientated work, namely the planning, design and production of the journeyman's piece. The presentation of the workpiece and the examinations in specialised knowledge and business administration in front of an examination board are at the end of the apprenticeship. Finally, the final apprenticeship examination (journeyman's examination) is taken in front of examiners from the Chamber of Commerce.

Head of department: Lukas Födinger

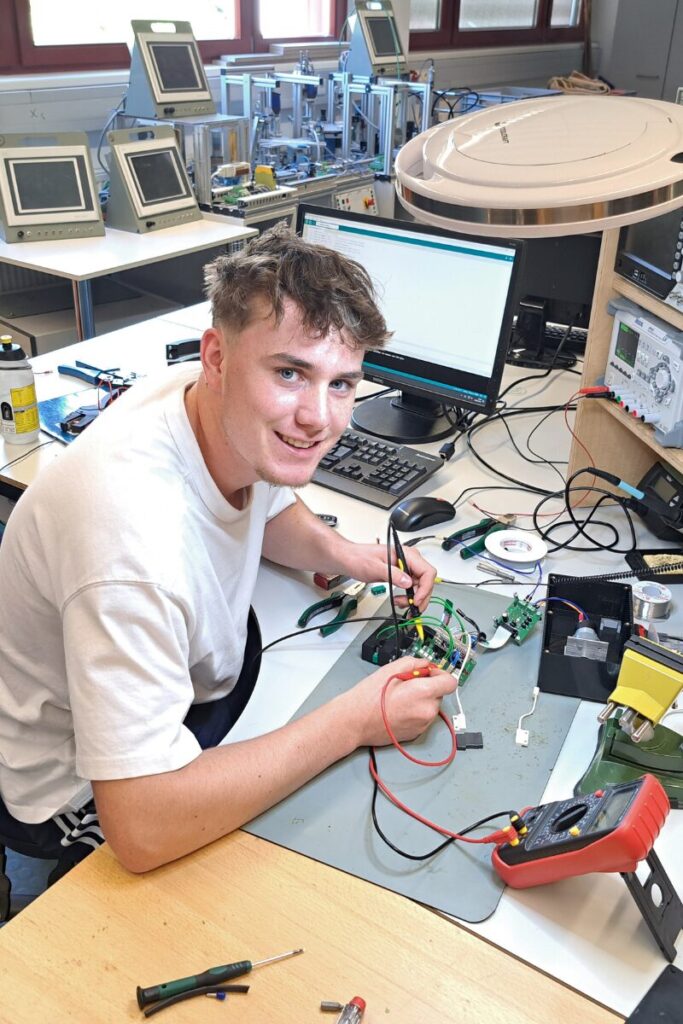

Mechatronics imparts knowledge in electrical engineering, electronics, mechanics and computer science. Devices and machines are built using ready-made components and the desired functions are defined using programmes. During the four-year training programme at the Felbertal work-study school, students are gradually taught state-of-the-art technical know-how and practical skills. Mechatronics requires a high level of technical expertise and independence in the development of solutions. Individual specialisations such as robotics are possible and desirable. The ability to work in a team and the development of project and time management skills are promoted at the factory school in order to be able to work successfully in planning and production.

All theoretical and practical skills of the mechatronics training programme must be represented in the final project of the eighth grade. It includes a theoretical, a planning and a practical focus. The presentation of the final project takes place in front of an examination board with representatives of the provincial guild and the Salzburg Chamber of Commerce and is held in English by some candidates.

Department heads: Norbert Prey, Patrick Schaidreiter

In the first year of the Joinery technology all manual woodworking techniques are learnt. The students produce a small piece of furniture in which as many classic wood joints and work processes as possible are used. This could be a Swiss stone pine chest, for example.

From the 2nd year of training, complex pieces of furniture are built, the level of difficulty of which increases from class to class. Particular attention is paid to clean workmanship, dimensional accuracy, surface quality, good design and, as the training progresses, production time.

In addition to practical training, the curriculum also includes specialised theoretical knowledge. An example: When a student produces a desk in the workshop, he draws it on CAD beforehand in technical drawing lessons and then uses a rendering programme to create a photorealistic representation of it on the screen.

At the end of the craft training programme, each student plans a journeyman's piece and produces it entirely themselves. The examinations are then taken in front of the examination board. Representatives of the regional guild are present at the presentation and assessment of the work.